Simplify Your L...

Hygiene Monitoring: ...

12th November 2019 Editorial by: rapidmicrobiology staff writer

The Fastest Way to Test for Listeria - Can it Get Any Faster?

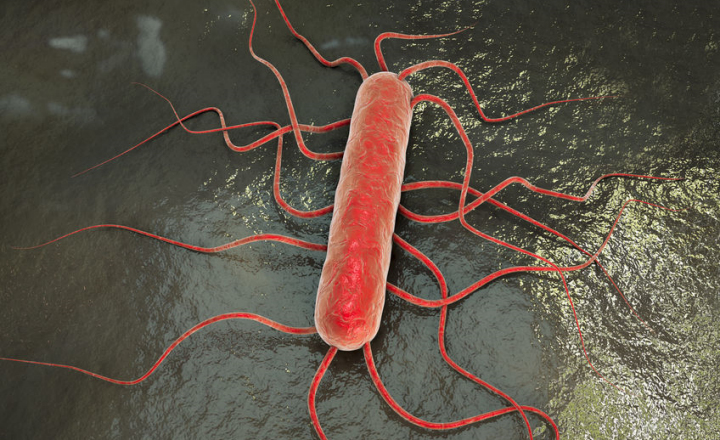

Listeria contaminations in the food industry are less common than other pathogens, but much more dangerous. According to EU data, Listeriosis is the foodborne disease with the highest rate of hospitalisations and fatalities.

Listeria, which is widespread in the environment, can contaminate many different types of food. However, ready-to-eat foods are particularly affected, as they do not require further cooking or reheating. One recent serious episode was associated with chilled roasted pork meat produced in the Spanish region of Andalucia in August 2019. The toll of the outbreak was more than 200 confirmed cases, with three reported deaths and six miscarriages.

In 2018, Neogen launched Listeria Right Now™, an environmental swab test that meets the food industry’s high demand for rapid and reliable monitoring for the presence of Listeria in the production line and surrounding environment. Rapidmicrobiology asked Neogen Product Manager Claire Chilton how Listeria Right Now works and why it can make an important difference for food manufacturers.

Q: Where does Listeria Right Now fit in a food manufacturer’s environmental monitoring program?

A: Listeria Right Now can be used effectively in environmental programmes both in the EU and in the US, where legislation and practices differ. In the EU there is some level of tolerance of Listeria for some products, like raw milk cheese. Environmental monitoring in the EU is based on HACCP, which uses a seven-point system and provides a systematic way of identifying food safety hazards.

The FDA, however, has zero-tolerance towards Listeria and FSMA’s environmental monitoring practice is based on an approach called Seek & Destroy (S&D). S&D is more test-intensive, while HACCP is more about reacting to food safety issues and putting a plan in place to rectify the problem continuously in the process.

Q: How important is it to detect the presence of Listeria rapidly?

A: Whenever there is a positive result in a food processing line, especially on direct food contact surfaces and closely adjacent areas (sampling zones 1 and 2 in FSMA), manufacturing has to cease, and a negative test result is required to restart.

Being able to quickly identify the source of the contamination is crucial, because it allows you to clean and sanitise the area thoroughly and stop the issue before it becomes a more serious problem.

Many tests on the market are based on PCR (polymerase chain reaction), which requires about 24 hours to get from sample to result. Other methods, such as ISO 11290-1 can take up to 48 or 72 hours. With Listeria Right Now, however, there is no enrichment stage. That means you can have results in less than one hour. There are other swab tests for Listeria on the market, but they still have to be incubated for a period of time in a selective broth.

When manufacturers take our system on board it's really pivotal for them because they can resume production sooner, with minimal impact on the productivity of the facility, meaning less disruption and huge time and cost savings.

Q: Are there other advantages to using Listeria Right Now?

A: A great advantage of Listeria Right Now is that you don't have to grow pathogens in your facility, which is something many manufacturers are concerned about, due to the risk of contamination. Another benefit is that it is a destructive test due to an added heat step, where after sampling, the swab is dipped into a lysis buffer, the heating step is carried out, and this effectively destroys any pathogens, if there are any, and reduces the risk of cross-contamination in the factory.

Q: What improvements did you bring to Listeria Right Now?

A: We were aware that another challenge for food manufacturers is to ensure that they’re not compromising the quality and safety of the product with a faster time-to-result.

With our method, we use ribosomal RNA (rRNA), which is present in much higher quantities than DNA in cells. This allows us to have a highly sensitive test without any enrichment. What’s more, rRNA will die off after 48 hours. With the Listeria Right Now system, a positive result indicates that contamination has been very recent.

Isothermal amplification is another technology we have applied. It works at a constant temperature of 56 degrees Celsius, without the need for thermo-cycling which is required with standard PCR methodology, allowing us to reduce time to result significantly.

Q: Does Listeria Right Now require a lot of training to be used properly?

A: We provide in-depth training for Listeria Right Now to our customers directly onsite as standard. The system is very easy to use, over a training session of two to three hours, we go through all the required steps, from how to swab the sample area correctly, how to pipette the sample, and how to read the results.

You wouldn’t need any particular skills to use Listeria Right Now. You just need a clean area to work in, and to follow the procedure described in the training. The system is very compact in size and can be packaged in a flight case, so it can also be used as a response unit that moves from site to site.

Q: What future improvements do you expect for pathogen tests? Can they get any faster?

A: When it comes to pathogens, swabbing tends to be more focused on Listeria. It’s a quite unique pathogen. It doesn’t have any indicator organisms, so the customers we work with are looking for it directly. With Salmonella, for example, you would be testing for same-family indicators, like Enterobacteriaceae.

I think the difficulty for a manufacturing facility is that there are so many locations and small areas involved, so swabbing is probably the best way forward. For a Listeria swab test, one hour is considerably much faster than any other method available, so I'm not sure whether it could get any faster!

Listeria Right Now has been validated by AOAC and NSF International and was winner of the 2018 Innovation Award from CFIA (Carrefour des Fournisseurs de l’Industrie Agroalimentaire).

For more information on Listeria Right Now visit http://bit.ly/32Hp0Bj or email microbiology_uk@neogeneurope.com.

|

Claire Chilton is Product Manager for ANSR and Pathogens at Neogen. She has an extensive background in microbiology and prior to her role at Neogen spent four years as a Research Assistant at the Nestlé research centre in Lausanne working on method development for microbiology methods. Claire has a further seven years experience working across a variety of industry roles including Development Scientist in microbiological media and Microbiology Technician for food products. |

Tags:

Date Published: 12th November 2019

Source article link: View

Simplify Your Listeria Workflow

Hygiene Monitoring: Are You Getting