How can a microbiology testing lab increase efficiencies, reduce costs, and get more done in a day without adding additional personnel? By streamlining the workflow to be as efficient as possible while maintaining full sample and results traceability. Historically, this has meant manually labeling samples and culture plates, and coding results in spreadsheets for documentation. It also meant spending significant amounts of labor hours on these activities. With advances in technology, these traditional, labor-intensive operations can be transitioned to more automated, streamlined workflows.

Laboratory automation offers many benefits. Method variability is reduced when replacing the human element with instrumentation. Labs can gain a 2 -3 fold improvement in precision and reduce labor costs twofold by automating a process. Automation can eliminate the need for additional laboratory personnel required to perform repetitive, routine tasks. A bonus is increased employee satisfaction, minimizing turnover and allowing lab technicians time to work on more complex methods and results analyses. Of course, the major gain is in lab throughput, which means a decrease in turnaround time for results, analysis, and report generation; and overall testing costs.

There are multiple hurdles to overcome when automating laboratory testing, especially when testing for microbial contamination in food. With a wide variety of matrices, sample sizes, and organisms, each food type can have its own unique methodology for sample preparation and testing. Another issue is the uneven distribution of the target organism, requiring large sample sizes or homogenization of multiple samples to achieve the testing precision needed to ensure food is safe to eat. In addition, the lab must select a robust laboratory information management system (LIMS). The LIMS must ensure efficient processing of all samples through all steps and storing the results; it also must record information for each process step, enabling traceability and chain of custody.

The lab must also consider the tests they run most often when automating processes. High-volume tests or repetitive tests should take precedent over occasional tests. This ensures automation of the activities that have the greatest impact on workflow efficiencies. In addition, the lab must determine what steps are simplest to automate. For example, sample pipetting can easily be automated if processing large numbers in a similar format. In fact, liquid handling is the most common type of process that is automated. When considering automation options, look for those manual processes that can be replaced with instrumentation and software capable of improving overall lab efficiency while maximizing method performance. Also, consider the physical space in the lab – and build flow diagrams to help identify the best equipment placement for maximum workflow outcomes.

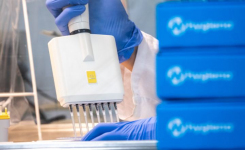

Some automated tools for microbial testing are as simple as instruments for sample preparation, especially when handling large sample numbers daily. For liquid handling, robotic systems can dispense and collect specific liquid amounts, such as adding reagents or washing samples. Such liquid handling platforms work with various container types, from tubes to multi-well plates and are designed to prepare samples for various downstream processes, such as plating, sequencing or PCR.

When considering PCR and automation, Hygiena™ offers the BAX® System kits for a wide range of microorganisms. When paired with the BAX® Prep Xpress liquid handling platform, automation of sample lysis for subsequent PCR assays is easy.

The BAX® System Kits are available as standard and real-time PCR assays, with results in hours. To aid with workflow, the BAX® System stores all results in computer-based software for analysis and interpretation. To complement this, the BAX® Prep Xpress handles sample preparation, reducing the risk of technician error while increasing pipetting accuracy and reliability. The automation system has onboard control features and software to minimize downtime by prompting technicians for any maintenance activities. It only takes up a small footprint (2 ft3), eliminating the need for extra benchtop space.

When it comes to microbiological laboratory testing, a multitude of complex, time-consuming workflow processes are needed. By smartly evaluating the labs’ need for automation to streamline these workflows, consider automation solutions such as the BAX® System and BAX® Prep Xpress to handle the most tedious tasks, such as sample processing. Hygiena™ can assist you in getting this workflow set up in your laboratory. Learn more about the BAX® System and BAX® Prep Xpress.