In the food manufacturing industry, brand reputation is everything. The cost of recalls and reputational damage can be huge. Recalls due to food pathogens, spoilage issues, allergens, mycotoxins, and microplastics are not just technical terms; they are threats that can erode trust and loyalty in an instant. That a food is safe to eat should be a given.

For quality control managers and food industry executives, the challenge lies in recognising these risks and addressing them head-on. Investing in comprehensive safety protocols can significantly boost your brand’s standing in the market.

Browse now to discover products for:

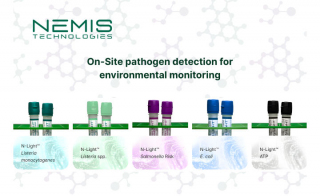

Surface and Environmental Sampling: Puritan's ESK® (Environmental Sampling Kit), includes a smaller swab for hard-to-reach spots and is available in four solution options: Buffered Peptone Water, Butterfield’s Solution, Letheen Broth or Neutralizing Buffer. Discover MWE's innovative environmental monitoring tools like the POLYWIPE™ Range, now available in an Easy Open Bag, which can be used as both a glove and a stomacher bag. The Nemis N-Light™ environmental monitoring solution sets a new standard for food safety, using unique bacteria-specific enrichment broths containing carefully designed bacteriophage cocktails to selectively eliminate competing microflora.

Allergens: Combined use of Prognosis' Allergen Free Series (Lateral Flow) and Allergen Shield Series (ELISA) allows both rapid in-plant screening and sensitive lab confirmation of allergen levels. They can be integrated into allergen monitoring plans (e.g., HACCP or ISO 22000 programs), helping manufacturers verify compliance with global safety standards and risk-based labelling guidelines. Romer Labs offer the AgraVision™ Pro application which reduces the need for subjective judgment by providing an automated reading of results. Introducing a hook line in the SENSIStripPowerLine kits from Gold Standard eliminates the risk of false negatives in highly contaminated samples, enhances the reliability of allergen detection, and safeguards consumers, particularly those with milk allergies.

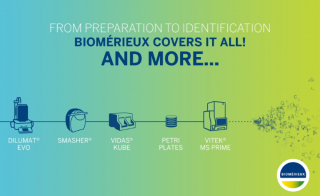

Automation/Workflow: Address skilled labour shortages in the food industry by improving laboratory workflow and automation, watch bioMérieux's video to discover how their integrated solution from sample prep to identification supports every stage of the food safety workflow. Conceived by Copan Newlab, the Cyclone is an innovative walk-away equipment that automates every step from serial dilutions to sample analysis.

Food Pathogens: Hygiena's foodproof® Salmonella plus Cronobacter Detection LyoKit reduces testing time to just 19 hours, streamlining workflows and minimising costs for manufacturers of infant formulas. Download a free eBook from Thermo Fisher Scientific, "Coloring the path to food safety excellence - a guide to chromogenic media for food microbiology testing" to get insights into how to choose and implement the right chromogenic media for your lab.

Water Testing: While Legionella remains a critical concern, water systems in food production facilities can also harbor a wide range of other microbial threats. The r-biopharm SureFast® molecular testing portfolio offers specialized real-time PCR panels designed to detect key pathogens and indicators relevant to food industry water systems.

Are you ready to safeguard your brand’s reputation? Learn more about effective food safety practices here and join the movement towards a safer food industry. Your commitment to quality and safety is not just a regulatory requirement; it's a promise to your customers.

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More

Find Out More