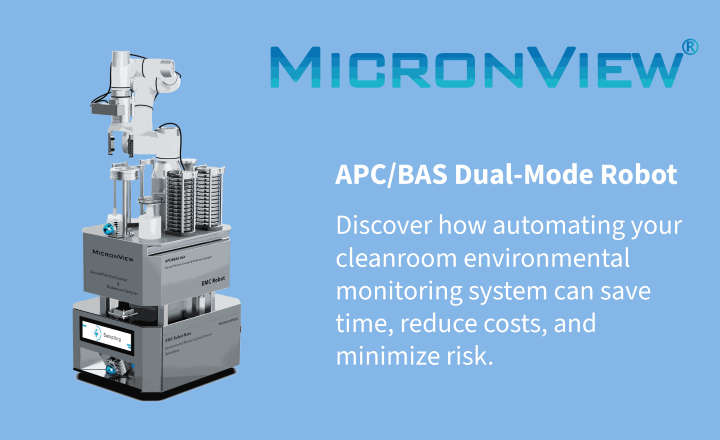

Environmental monitoring is necessary for cleanroom quality assurance, but manual sampling can be costly, time-consuming, and introduces opportunities for human error. MicronView’s Dual-mode Robot offers a transformative alternative: automated viable and non-viable sampling within a single, coordinated system.

To demonstrate the improved efficiency of an automated system, the following example compares traditional cleanroom monitoring performed by technicians with monitoring by MicronView’s Dual-mode Robot, equipped with both a BioAerosol Sampler (BAS) and an Airborne Particle Counter (APC).

Example Scenario:

- A 150 m² Grade C cleanroom with 40 total sampling locations, each requiring aseptic handling, documentation, and compliance with GMP standards.

- 20 viable sampling points (100 L/min, 5 minutes each)

- 20 non-viable sampling points (28.3 L/min, 1 minute each)

Manual Monitoring: Labor-Intensive and Prone to Error

If sampling is completed manually, the entire process takes an estimated time of ≈ 5.5 hours / 6 person-hours.

Key steps:

- Preparation (45 min): Gowning, disinfection, labeling, and setup.

- Viable Sampling (165 min): Air sampler setup, flow verification, plate handling, and disinfection between points.

- Non-Viable Sampling (60 min): Probe positioning, sampling, and manual data recording.

- Post-Sampling (60 min): Equipment cleaning, plate transfer, and data transcription.

Even skilled technicians face challenges like manual data transcription errors, cross-contamination risks, and clearance/resampling delays.

Automated Monitoring with MicronView’s Dual-mode Robot:

MicronView’s Dual-mode Robot combines a BioAerosol Sampler (BAS) and Airborne Particle Counter (APC) in one autonomous platform.

- Navigates via LiDAR + SLAM mapping (±2 cm accuracy).

- Follows validated sampling routes programmed in EMC Robot Software.

- Sequential workflow:

- BAS collects 500 L viable samples (5 min).

- APC performs 1-min particle count at same location.

- Barcoded plates and timestamped data ensure full traceability.

- Automated alerts, resampling triggers, and digital reporting eliminate manual logging.

After sampling is complete, the robot docks itself and reports the data instantly, ready for QA review.

Efficiency Comparison (Manual vs. Dual-mode Robot)

- Personnel: Manual monitoring typically requires 2-3 technicians, while the robot can be managed by a single subject matter expert.

- Total Time: Manual monitoring takes about 5.5 hours, compared to approximately 2.5 hours of mostly unattended robotic operation.

- Labor Effort: Manual rounds demand around 6 person-hours, whereas the robot requires less than 0.5 person-hours of human oversight.

- Error Risk: Human sampling and transcription introduce moderate error risk, while the robot’s automated, repeatable process keeps risk minimal.

- Data Logging: Manual processes require manual data entry, but the robot provides fully automatic and traceable data capture and electronic reporting.

Outcome:

- ~55% reduction in total time

- >90% reduction in labor

- Consistent, traceable, validated sampling

Takeaway: A New Standard for Cleanroom Efficiency

By removing human variability, the Dual-mode Robot minimizes contamination risks and improves data integrity. Real-time data flow and automated alerts support Annex 1 compliance and proactive contamination control.

In this example, a full day of manual work becomes two hours of unattended automation, with no gowning, no manual logging, and no transcription errors. MicronView’s Dual-mode Robot redefines cleanroom monitoring as fast, clean, and ready for the next generation of pharmaceutical manufacturing.

Learn more about MicronView’s Robot line