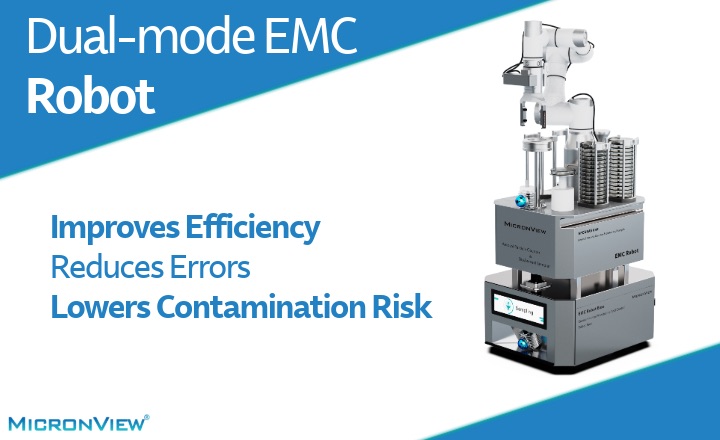

As environmental monitoring standards in pharmaceutical manufacturing become increasingly stringent, cleanroom operators are under pressure to reduce contamination risk, improve data traceability, and maintain strict compliance with global regulations. MicronView’s APC/BAS Dual-Mode Robot offers a comprehensive and forward-looking solution to these challenges by combining two traditionally separate processes, plate-based viable air sampling and total airborne particle monitoring, into a fully autonomous mobile platform.

Rethinking Cleanroom Sampling Practices

Manual environmental monitoring relies on trained personnel entering controlled areas, handling sampling equipment, and recording data by hand. While this has been the industry norm for decades, it introduces multiple sources of variability: inconsistent sample placement, human error in recordkeeping, and increased contamination risk due to gowning and cleanroom entry.

The Dual-Mode Robot eliminates these issues by automating both viable and non-viable air sampling. A precision 6-axis robotic arm is used to place and retrieve 90 mm agar plates for microbial monitoring, while an onboard airborne particle counter continuously captures total particle data. By removing the need for human intervention during sampling, the robot improves reliability, repeatability, and overall environmental control.

Key Features and Advantages

- Integrated Dual-Mode Monitoring

Combines viable air sampling and non-viable airborne particle counting in one system, eliminating the need for separate instruments or workflows. - Precision Robotic Handling

The 6-axis robotic arm delivers plate placement accuracy of ±0.02 mm, ensuring highly reproducible sample collection every time. - Autonomous Navigation

Equipped with LiDAR, IMU sensors, and wheel odometry, the robot can safely navigate pre-mapped routes in the cleanroom, locate sampling positions, and return to its docking station for recharging. - Real-Time, Encrypted Data Capture

All sampling data is timestamped, encrypted, and stored locally on an onboard industrial PC and MicronView’s EMC Software. Data can be exported in standard formats (CSV, XLS, PDF) or integrated directly into LIMS systems. - Smart Software Integration

The system is controlled via MicronView’s EMC software and supports custom scheduling, real-time monitoring, and system diagnostics. - Cleanroom-Ready Engineering

Built with a 316L stainless steel chassis and sealed design, the unit is resistant to VHP, isopropanol, and other sporicidal agents, making it suitable for aseptic environments. - Automated Operation

Operates up to 8 hours per charge with automatic docking and recharging. Ideal for overnight or continuous sampling without technician oversight. - Supports Regulatory Compliance

Fully aligned with GMP and Annex 1 requirements for continuous viable particle monitoring and traceable environmental data management.

Real-World Application Example: Grade B Cleanroom

In Grade B aseptic filling areas, where environmental monitoring must be precise and consistent, traditional methods often require technicians to enter controlled zones multiple times per day to manually place plates and operate particle counters. This increases gowning burden, exposes clean areas to contamination risk, and introduces inconsistencies in sample timing and handling.

With the Dual-Mode Robot, all sampling tasks are completed autonomously based on preprogrammed schedules. The robot navigates directly to designated locations, performs both viable and non-viable sampling, and returns to its docking station without requiring technician intervention. Sampling routines can be set to occur outside of staffed hours, freeing up personnel for more critical tasks.

All data is logged in real time, encrypted, and immediately available for review or integration into quality systems. This not only simplifies audit preparation but also ensures rapid response to deviations. The result: better environmental control, improved resource allocation, and a more robust contamination control strategy.

Summary

MicronView’s APC/BAS Dual-Mode Robot transforms environmental monitoring by automating both key sampling workflows. It minimizes human variability, enhances traceability, and streamlines compliance, making it a powerful tool for modern cleanroom operations.

Learn more about the APC/BAS Dual-mode Robot here.