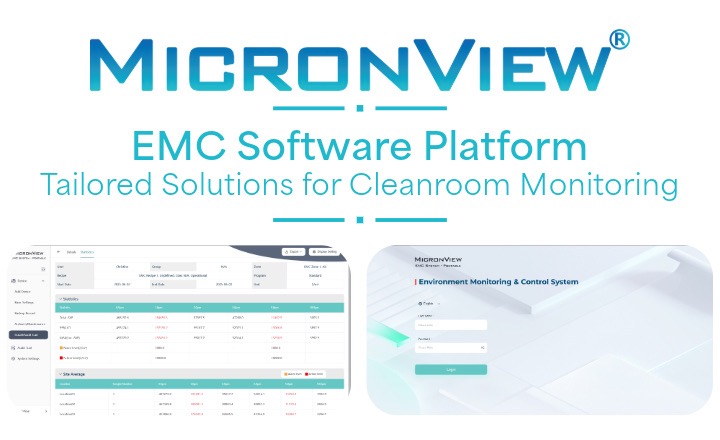

MicronView’s Environmental Monitoring and Control (EMC) Software suite is designed to work seamlessly with our range of monitoring devices. It offers comprehensive control, data analysis, and contamination management in pharmaceutical and healthcare facilities. The EMC system is highly flexible, providing four distinct software sub-modules tailored to different device types and monitoring needs.

1. Portable Instrument Platform: The Portable EMC Software module is designed for facilities utilizing our mobile monitoring solutions. It integrates MicronView’s portable devices, including mini APC, BAMS, and BAS, allowing users to configure and manage multiple devices from a single interface. Features include:

- Multi-device Management: Sync sampling schemes across devices.

- Data Retrieval: Centralized data analysis and reporting.

- Audit Trail: Ensures compliance and traceability.

Use Case Example: A pharmaceutical facility conducts routine classification across cleanrooms using our mini APC. They utilize the Portable EMC Software module to synchronize sampling schemes and streamline data collection, ensuring ISO-compliant results.

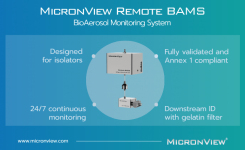

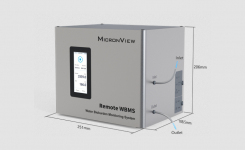

2. Remote Instrument Platform: The Remote EMC Software module provides centralized control for fixed remote devices like Remote BAMS, Remote APC, and Remote BAS. It allows real-time monitoring with immediate alerts for contamination risks. Key features include:

- Centralized Control: Manage all remote devices from a single dashboard.

- Real-Time Alerts: Receive instant notifications for breached alert and action levels and view the data in real-time.

- Seamless Data Integration: Automatic data uploads for analysis and report generation.

Use Case Example: A biopharmaceutical facility uses the Remote EMC Software module to monitor isolators and filling lines 24/7 with both the Remote BAMS. This reduces the potential impact of a contamination event and ensures continuous sterility without frequent cleanroom entry.

3. Robotic System Platform: The Robot EMC Software module is tailored for environments requiring robotic automation. It controls MicronView’s line of EMC robots for particle and microbial detection, monitoring, and disinfection. Features include:

- Automated Sampling: Robots autonomously perform sampling and disinfection task using SLAM technology for precise movement.

- Data Retrieval: Robots integrated in the EMC software system will have sampling data automatically uploaded for centralized management.

Use Case Example: A cleanroom facility uses the EMC Dual-mode robot to automate routine microbial and particle sampling, improving efficiency and reducing contamination risks.

4. Full EMC Software Suite: The Full EMC Software Suite integrates all the above platforms into a single, comprehensive solution. It provides advanced data analysis, risk-based sampling plans, and task management. Key features include:

- End-to-End Risk Management: Proactively manage contamination control.

- Comprehensive Data Analysis: Consolidate data from all devices for actionable insights.

- Regulatory Compliance: Ensure continuous compliance with ISO, EU GMP, and FDA standards.

Use Case Example: A pharmaceutical company uses the Full EMC Suite to manage cleanroom validation and continuous monitoring using a variety of MicronView devices, ensuring compliance from day one and streamlining long-term monitoring.

MicronView’s EMC Software is designed to meet the diverse needs of cleanroom facilities, offering scalable solutions for effective environmental monitoring, contamination control, and regulatory compliance.