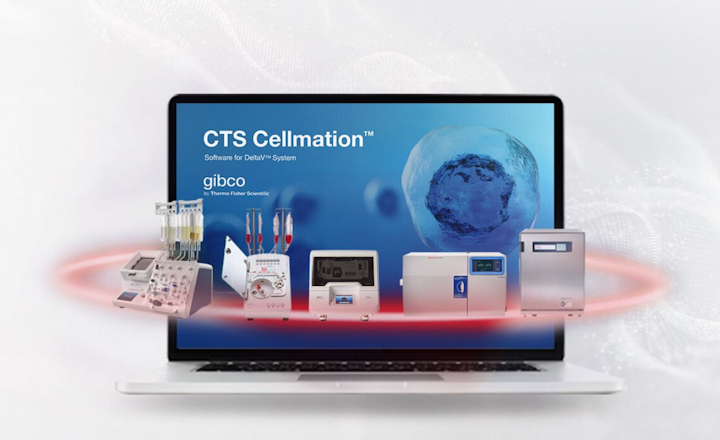

To optimize clinical manufacturing processes for innovators developing breakthrough cell therapies, Thermo Fisher Scientific has launched the Gibco™ Cell Therapy Systems (CTS™) Cellmation™ Software, a first-of-its-kind automation solution designed to connect and integrate workflows across multiple Thermo Fisher Scientific cell therapy instruments while enabling cGMP compliance.

This new offering can help eliminate the need for costly custom software projects and extensive validation, saving valuable time and resources during the cell therapy manufacturing process and helping to deliver these promising curative therapies more quickly and safely to patients.

The cell therapy manufacturing process is estimated to include upwards of 40 manual touchpoints, increasing opportunities for errors and contamination that can lead to failure and delay potentially life-saving treatment for those who need it most. The CTS Cellmation Software, powered by Emerson’s DeltaV™ Distributed Control System (DCS), connects Thermo Fisher’s cell therapy instruments within a single, user-friendly interface, reducing the number of manual touchpoints required. By establishing an automated workflow across multiple stages of cell therapy manufacturing, CTS Cellmation Software helps enable traceability, repeatability and 21 CFR Part 11 compliance with secured data connectivity.

“As our biopharma partners continue to expand their cell therapy pipelines, CTS Cellmation Software enables digital integration of unit operations, helping to ensure reproducibility, traceability, and data security required for scaling cGMP manufacturing processes,” said Betty Woo, vice president of cell, gene and advanced therapies at Thermo Fisher Scientific. “This new software offers a fully validated, off-the-shelf automated solution to digitally connect and control Thermo Fisher fit-for-purpose instruments, ultimately helping deliver these potentially transformative medicines to patients more efficiently.”

Thermo Fisher is committed to streamlining manufacturing for cell therapy developers and all cell therapy platforms currently in development will also align with and connect to this digital, automated framework. At present, CTS Cellmation Software connects core Thermo Fisher Scientific cell therapy instruments, including solutions from our Gibco CTS portfolio. These instruments, along with their supporting consumables and software products enable GMP-compliant, closed-system manufacturing.

- Gibco CTS DynaCellect™ Magnetic Separation System

- Gibco CTS Rotea™ Counterflow Centrifugation System

- Gibco CTS Xenon™ Electroporation System

- Thermo Scientific™ Heracell™ Vios™ CR CO2 Incubator

- Thermo Scientific™ Cryomed™ Controlled-Rate Freezer

To learn more about Thermo Fisher’s Gibco CTS Cellmation Software, please visit thermofisher.com/cellmation.

Watch webinar 'Explore automation solutions for cell therapy workflows'