The food industry has recently faced some tough challenges, with increased supply chain pressures, and complex and constantly changing regulations. All whilst working on reducing margins, skilled staff shortages, and trying to meet environmental targets. Do the challenges of producing safe food now require a completely new approach, one that can leverage the latest techniques in laboratory-based analysis, data handling, and AI?

bioMérieux is taking up this challenge and is committed to being the trusted partner of this new era with its 'Augmented Diagnostics Approach for Food Safety and Quality'.

This concept has been specifically designed to integrate the most up-to-date technologies to simplify what has been, up to now, a complex task. In this exclusive interview with Grégoire Kebabtchieff, VP Global Marketing and Strategic Accounts, Food Safety & Quality business at bioMérieux, we discover more about bioMérieux's novel approach and what makes it a game changer for the whole supply chain from manufacturers to distributors and retailers. How can businesses use Augmented Diagnostics for Food Safety and Quality to protect their consumers, prevent recalls and factory shutdowns via proactive microbiology testing, data analytics and preventative measures?

Q: What’s driving a need for change in approach to food safety?

Grégoire Kebabtchieff: The food industry is at a turning point.

Whilst adapting to consumers' new food experiences such as novel protein sources and clean labeling, the food industry is also undergoing major strategic changes challenging the way our customers need to approach food safety and quality. Post-Covid recovery as well as major political and macro-economic disruption have been impacting our industry. The new standards are driven by inflation, uncertainty, availability, and retention of skilled staff and these have re-centred the food industry around financial performance metrics.

These forces combined with the emergence of new technologies, are opening up a new era for a digital approach allowing automated processes, improving robustness, and shifting to a leaner manufacturing model.

Data is now king as it can be turned into actionable insights. This includes the way organizations are assessing their carbon footprint and communicating how they plan to reduce their own impact on the planet.

bioMérieux's vision is clear - food safety is evolving to meet the needs of this new business paradigm. Together with our historical mission to protect consumer’s health and our customers' reputations through high-quality and safe products, food safety is now also an essential part of an economic equation where a significant impact can be made all along the manufacturing journey and can help optimize the bottom line for the food sector.

Q: Augmented Diagnostics – what exactly does it involve, how is it different from existing food safety testing?

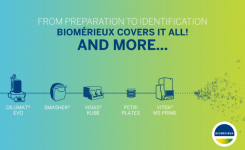

Grégoire Kebabtchieff: Traditionally food safety test results are generated in the lab and viewed as 'stand-alone'. With its proven background in pioneering next-generation developments, bioMérieux has understood that in the future, food safety will no longer rely on a single test result, it will increasingly need to provide actionable insights to its customers.

Over the last 3 years, we have invested in molecular biology, genomics, data science, bioinformatics, and digital tools with the goal of moving away from simply reporting test results towards producing data that is genuinely meaningful. As a result, this insight data is AUGMENTING or adding value to a customer's DIAGNOSTIC findings, and the risk highlights it provides will assist our customers in making better, more informed, and faster decisions.

Q: There are many demands from food processors, how will Augmented Diagnostics help? Grégoire Kebabtchieff: Based on the specific challenges that customers are facing, (and these will be different depending on which industry they operate in), we are driving operational efficiency in 3 main areas:

- Supply Chain Assurance: will help our customers to better understand the past through smarter and more dynamic risk assessment tools

- Manufacturing Excellence: will optimize the present by turning test results into actionable insights

- Consumer Protection: will improve our customer's quality systems so they can better anticipate and prevent. Make smarter, more informed, and faster decisions. And ultimately provide the safest possible products of the highest quality to their consumers.

Q: Businesses can find change difficult, especially with a shortage of skilled staff, will this be easy to implement?

Grégoire Kebabtchieff: Employee shortage is a major concern and the outcome of 'the great resignation' can be a loss of knowledge and good practices. It is exactly this type of experience shortage that augmented diagnostics can help with. With the right tools, we believe that change within organizations is very achievable and we offer a bold and innovative approach to make this easier, via the following combination:

- Digital learning to train employees on how to conduct environmental monitoring

- Streamlining execution via digital platforms such as ENVIROMAP where the process is 100% automated and can be applied by any trained employee even one with a limited tenure

- Leverage data science and bio-informatics tools to continuously help improve risk monitoring and risk anticipation. In the end, make the change not a one-off issue but a continual journey ideally adapted to today’s paradigm change.

Q: How will a food business justify the costs?

Grégoire Kebabtchieff: Short answer. We call it ROI!

Our customers do not need to buy new instruments or reagents, so we are not talking about new capital expenditure costs and associated maintenance fees.

The value to a business comes from demonstrating where we can streamline critical business pinch points, such as inventory holds, supplier raw materials approvals, run times, product wastage, sanitation downtime, and overall non-quality costs. By considering improvements that can be made through the entire process, end-to-end all along the entire food value chain, our customers can make significant financial savings.

Q: What makes bioMérieux uniquely positioned to deliver this innovative solution?

Grégoire Kebabtchieff: This year bioMérieux is celebrating its 60th anniversary with 4 generations at the head of our company who have all embraced the true pioneering spirit that makes bioMérieux a world leader in the diagnostic space.

Our company is committed to a public health mission, and besides this goal we invest more than 10% of our revenues every year in R&D. We employ very reputable scientists and we have a proven track record of retaining our best talent, people remain our most precious assets. For the customer, this means an expert sales and technical support team is on hand to help them choose the products that best suit their business model and to provide technical assistance when needed.

Q: Can you give an example of where this solution has been implemented, what have been the benefits?

Grégoire Kebabtchieff: Recently we have been helping a number of companies in the beverage industry to improve their operational efficiency in the face of challenges posed by microbial spoilage.

Based on their very specific situation and complexity we have built a turn-key program where:

- We streamlined their environmental monitoring program via our ENVIROMAP digital platform

- We have acquired and analyzed their testing data and turned them into insights to identify critical risk areas and critical spoilers. In this case some specific yeast and molds

- We have used metagenomic data to characterize these microorganisms precisely through what we like to now call SPOILAGE MAPPING

- As the specific microorganisms identified were routinely holding up product release for 7-10 days and the primary cause of wastage, we set up in 6 months an ad-hoc molecular detection PCR assay to allow decisions to be made within 48h max.

- We have set a dynamic data model to monitor the microbial data relevance and an adaptive sampling process to ensure that hot spots are consistently monitored as they evolve time after time.

Ultimately, zero risk does not exist and will probably never exist.

But turning data into information, using genomics to improve knowledge of risks, leveraging technology to better understand and anticipate risks, this is part of the new era and our vision of the future of food safety. This is the goal of bioMerieux, which promises to be 'YOUR TRUSTED PARTNER IN AUGMENTED DIAGNOSTICS'

To discover more about how augmented diagnostics can improve your food safety and bottom line, visit www.biomerieux.com or use the Request Information button below to connect directly.