In the beverage industry, using juice concentrate is a common practice that offers several advantages. Concentrates, such as orange juice or cola syrup, allow manufacturers to produce beverages efficiently while reducing logistical costs. By minimizing the transportation of water - the essential component in drinks - this approach not only lowers shipping expenses but also supports sustainability efforts by decreasing the carbon footprint associated with long-distance transport. This straightforward process mirrors how the ReadyStream® system prepares microbiological media, much like fruit juices or soft drinks are diluted from their respective concentrates.

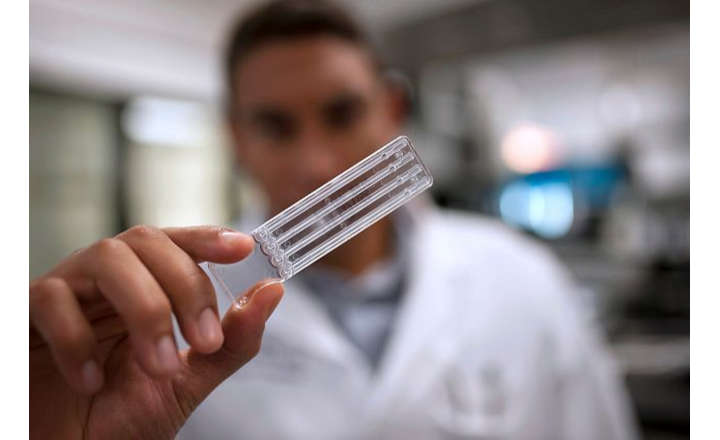

The ReadyStream® system uses a pre-irradiated bag filled with granulated dehydrated culture media (BPW, Half FRASER or TSB), reconstituted with DI-water filtered through a 0.22 µm sterile filter. This creates a concentrated media stock solution that remains viable for 10 days. When liquid media is needed for testing, a simple push of a button dilutes the required amount of this stock solution with additional sterile filtered water, conveniently dispensing the resulting media at the desired temperature and concentration (from 0.1 to 2.0x) directly onto the food sample.

By streamlining workflows and addressing the challenges of traditional methods, the ReadyStream® system provides an efficient and environmentally friendly solution, similar to the convenience of using concentrated juice instead of preparing fresh juice from scratch.

How Does the ReadyStream® System Streamline Workflow?

In-house media preparation is resource-intensive and requires significant manual effort for mixing, filling, and cleaning. Ready-to-use media present their own challenges, as they come in large, heavy bags that are cumbersome for operators to handle. Additionally, if pre-heated media is required, it must be warmed in an incubator before use, adding another step.

With the ReadyStream® system, you can install the filter set and media bag in less than 20 minutes, allowing for the preparation of up to 100 liters of culture media from just one bag equivalent to 20 traditional 5 L ready-to-use media bags. This smart and innovative approach eliminates the cumbersome handling and carrying of multiple heavy bags, significantly reducing waste. Additionally, the ReadyStream® system can pre-heat the media to a maximum of 42°C, eliminating the need for pre-heating in an incubator.

Benefits of the ReadyStream® System

The ReadyStream® workflow revolutionizes media preparation by eliminating cumbersome manual tasks, making it an indispensable tool for laboratories involved in microbiological food testing.

- Time & Labor Efficiency: The system's workflow minimizes the need for constant operator involvement, allowing laboratory personnel to focus on other critical tasks.

- Ecological Footprint: A comparative study done by an independent lab showed that the system uses up to 99% less energy and 89% less water than traditional methods, leading to lower operational costs and a smaller environmental footprint. It also significantly reduces plastic waste compared to ready-to-use media bags.

- Regulatory Compliance: The ReadyStream® media are released under accreditation to meet various regulatory requirements for food testing. The convenient pre-heating feature ensures compliance with regulations that require pre-warmed media, which is especially important for large sample sizes.

- Compact & Light: The ReadyStream® bags are compact and lightweight, taking up little space in the warehouse and making them easy for lab technicians to carry.

Ready to simplify your testing workflow? Visit our website to learn more: www.sigmaaldrich.com