Listeria monocytogenes is a Gram-positive bacterium that is among the leading causes of death from foodborne illness. Of its 13 serotypes, three are associated with the vast majority of foodborne diseases. But there is a new kit on the block! Swiss start-up NEMIS Technologies AG specializes in developing simple, safe, and on-site pathogen testing solutions. Their detection test for Listeria monocytogenes is currently commercially available in Switzerland and France.

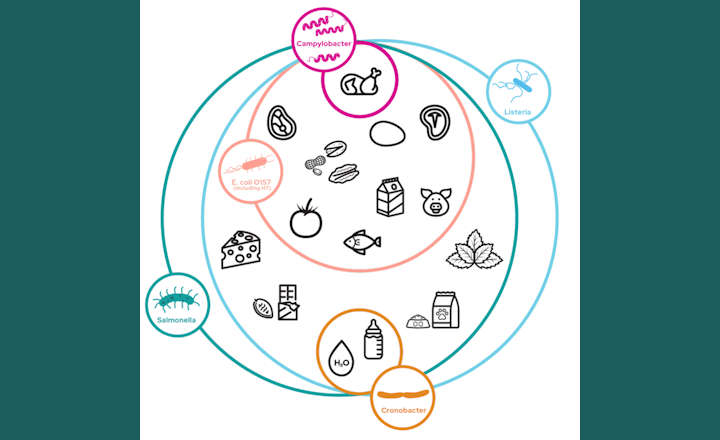

Did you know that you invite Listeria monocytogenes into your factory every day?The natural home of Listeria monocytogenes is in the fields. It is thus present in the soil, water, and even on harvested vegetables. As long as contaminated crops with Listeria monocytogenes have not entered a factory, the organism does not cause any harm and is therefore termed a saprophyte. Yet, most food manufacturers are inviting Listeria monocytogenes into their factories every day. Every piece of raw material could potentially harbor Listeria monocytogenes. Nevertheless, most raw and fresh produce is consumed without anyone getting sick. Listeria monocytogenes primarily affects people with a weak immune system and requires specific conditions to grow in food to reach an infectious dose. Nonetheless, there is cause for concern: Listeria monocytogenes can multiply from meager numbers and reach dangerous levels, even at fridge temperatures. Therefore, preventing even minimal contamination of foodstuffs is crucial.

Fresh and leafy produce: Listeria in your factory environmentPlants live until the very moment when they are harvested, after which they become highly perishable. To slow this process, plants are kept cold and may be packaged in a modified gas atmosphere to inhibit microbial activity. From this point onwards, produce remains refrigerated up until the point of consumption. Crucially, this is the very environment Listeria monocytogenes thrives in, as it has an advantage over other pathogens.

NEMIS Technologies AG has produced this short informative video explaining where Listeria monocytogenes is most commonly found in the production of fresh and ready-to-eat produce.

What critical control points should you consider?

1. Water re-use systems

Ready-to-eat fresh and raw products are washed in chilled water, which is most likely re-used. This makes water re-use systems a critical point as it provides Listeria monocytogenes with optimal conditions to grow.

2. Air conditioning systemsChilling, refrigeration, or air conditioning systems are required to keep food cold. The warm and moist air is sucked into these systems, where it is converted into cold, dry air. The water condenses on the metal coils of these systems, providing another niche for Listeria monocytogenes to grow in. Furthermore, if an air conditioning system is contaminated, it can act as a vector and can spread the pathogen all over the factory. If these systems happen to be located directly above vulnerable parts of the production process, condensate may drop onto the exposed area and cross-contaminate products.

3. BiofilmsA biofilm is a thin but robust layer of mucilage adhering to a solid surface, containing a consortium of microorganisms and food residue. Biofilms are typically associated with moist and wet surfaces. In the production of fresh and raw produce, there are perfect conditions for biofilms to accumulate on the equipment where the vegetables are washed, drained, and cut. If organisms such as Listeria monocytogenes grow within biofilms, they are more difficult to kill with disinfectants or remove by cleaning and are thus more likely to re-contaminate the fresh vegetables being processed.

Your tool of choice for more effective "seek and destroy" risk managementN-Light™ Listeria monocytogenes is a qualitative test method for the rapid detection of Listeria monocytogenes in food processing areas, which allows for immediate corrective actions thanks to short time-to-results. The N-Light™ is designed to free you from the constraints of laboratory infrastructure and the dependence on external partners by enabling safe on-site testing anytime by anyone.

"We have had a great experience with the N-Light™ rapid test. We have really fast results, it is incredibly easy to use, and we are happy that there will be more tests available in the future." Elisa Stamm, Quality Manager Kellermann AG

Visit NEMIS Technologies for details or get in touch with us today, using the green "Request Information" button below, and take back control over your schedule, priorities, and budget.