Production Managers across an array of industries are set to revolutionize their operations with EIT International's Gappscan G2™. This innovative plate heat exchanger (PHE) integrity testing system offers a host of benefits, optimizing production processes and ensuring uncompromised product quality.

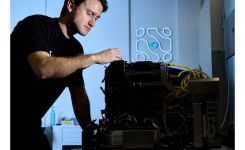

The Gappscan G2™ is designed for real-time examination of internal PHE surfaces to detect imperfections that might host contaminants. Through specialized multi-fit clamps, the Gappscan™ seamlessly integrates with PHEs, acting as a unified unit. By introducing water and employing the Bernoulli principle to pressurize the system, even the tiniest pressure fluctuations, as small as 1µm, are recorded by the Gappscan™. The results are conveniently stored in preloaded software on the accompanying tablet, facilitating data integration into preventative maintenance programs.

This swift testing system delivers accurate results within 5 minutes without the need for PHE disassembly, thereby minimizing production downtime.

Industries such as dairy, beverage, and brewing stand to gain significant advantages from Gappscan G2™. Detecting internal leaks is crucial, as cracked heat exchanger plates often display no visible symptoms. Timely detection with Gappscan G2™ prevents product contamination, waste, and costly recalls.

Compared to traditional PHE testing techniques, Gappscan™ technology stands out as a safe, fast, and cost-effective alternative. By utilizing only pressurized water, Gappscan G2™ eliminates the need for PHE dismantling. In contrast, traditional methods involving dye penetrants and chemicals necessitate time-consuming dismantle, up to 48 hours per test, and pose environmental challenges.

Gappscan™'s proprietary technology empowers Production Managers to schedule frequent inspections without disrupting operations. The included tablet's advanced software provides detailed results beyond simple "pass" or "fail" outcomes. It identifies and reports minute cracks and defects, enhancing overall efficiency.

With Gappscan G2™, internal surface examinations are simplified and more frequent, enhancing both audit compliance and preventative maintenance programs. EIT International's Gappscan G2™ marks a significant step towards streamlining production processes while ensuring top-tier product quality.

To discover more, or discuss your requirements visit EIT International or use the Request Information to contact the supplier directly.