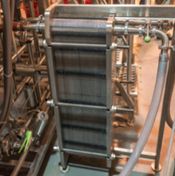

The Gappscan™ G2 has been developed specifically to detect cross-contaminating defects in plate heat exchangers across regulated industries, including dairy, food, brewery, and pharmaceutical.

Due to their construction and operating method, most damaged or defective heat exchanger plates will show no symptoms of defect externally. If not found in good time, the product passing through the PHE can become contaminated, leading to waste and potentially expensive recalls of finished product.

While there are other types of traditional test procedures such as dye penetrants, chemicals, and gas available, these methods have some serious disadvantages. As invasive test practices, these methods require the PHEs to be taken apart and then deep cleansed after tests; this can mean an exchanger being out of service for as much as 48 hours, just for one test. Additionally, there is an environmental impact consideration with the disposal of the test substances; the dye or gas used needs to be disposed of correctly and needs to be thoroughly cleaned from the heat exchangers before they can enter back into the production process. Test sensitivities can also reduce with volume and therefore become less reliable when testing large plate heat exchangers. These testing methods can only pass or fail a heat exchanger, they cannot determine the size of the defect or the leakage rate, making them of less use for preventative maintenance programmes.

The Gappscan™ G2 system can be deployed on all types of plate heat exchangers and, as a non-invasive integrity testing technology, there is no requirement to dismantle PHEs. This means that not only is there minimal downtime, but testing can be carried out more often if required and across multiple PHEs in one day. As the Gappscan only uses water (under pressure) to conduct tests, there are no harmful materials to dispose of or clean from the exchanger, making compliance to environmental impact guidelines easier to attain.

An additional benefit of the Gappscan™ system is that proprietary software preloaded on the Gappscan tablet offers more advanced results than a simple “pass” or “fail.” It is sensitive enough to identify and report numerous cracks and defects as small as a few microns in diameter, with the results available immediately.

A full test equipment system, contained in a single suitcase-sized holdall, that can be operated by a single person, which presents and records accurate test results within 5 minutes!

The Gappscan™ G2 is available to lease, allowing your in-house maintenance team to assess and track the behaviours of your PHEs without needing to wait for engineer visits from a third party and the charges incurred. Another benefit of leasing your unit is that you don’t have an upfront capital expenditure to justify, instead, monthly charges are spread in an easily forecastable manner. Additionally, your unit will always be the most up-to-date version, with calibration and servicing performed annually by EIT International.

For further information on Gappscan™ G2, please get in touch, visit www.eit-international.com or use the Request Information button below to contact the supplier.