Hygiene monitoring is a critical step in food production plants and other industries and markets to minimize the contamination risk of products and personnel within applicable environments. This is achieved by routinely verifying the effectiveness of cleaning and disinfection practices for equipment, personnel, and high-touch surfaces.

The MVP ICON® is a pioneering system that measures and records ATP and other key HACCP parameters AND provides new management tools. Designed with quality management in mind, the MVP ICON® Dashboard software provides a real-time snapshot of key program metrics that are essential to managing your HACCP program.

MULTI-VARIABLE PARAMETERS – One Instrument Does it All!

- One instrument measures multiple key quality indicators such as, ATP, pH, temperature, and conductivity/concentration.

- Instrument-guided calibration process satisfies HACCP and GMP requirements that all measurement systems can be calibrated and documented.

- Conductivity Probe allows for the most accurate measurement of cleaning and sanitizing reagents, ensuring sanitation effectiveness while reducing overall chemical costs.

- pH Probe′s non-glass design is ideal for in-plant use.

- Single-point calibration and pierced, stainless steel tip make Temperature Probe suitable for most applications between -20° to 105°C.

The detection of ATP through bioluminescence is a well-established and widely used indicator of surface hygiene and cleaning efficacy in food processing. Visual inspection is not an adequate critical control for surface hygiene and the lengthy time-to-result of microbiological test methods (from 2 - 7 days) make them ineffective for hygiene monitoring. ATP detection with the MVP ICON® provides results in 10 seconds allowing for immediate "go/no-go" decisions to be made prior to the start of processing and allows for correction actions, when necessary, to be taken immediately. ATP is a molecule that is found in all living cells, including: bacteria, yeast, mold and all organic matter. After cleaning and/or sanitizing, food processing equipment and the plant environment is tested for ATP. If cleaning/sanitizing has been effective, ATP levels should be low.

Features and Benefits

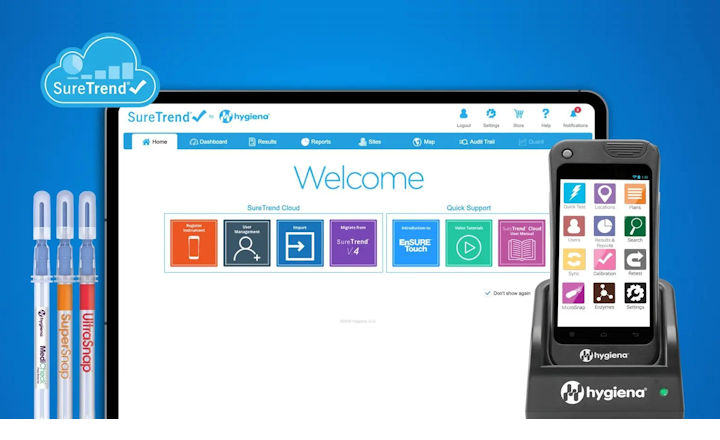

INSTRUMENT DESIGN - Next Generation User Interface

- Industry′s first touch screen application features advanced pressure-sensitive technology allowing for simple operation – even with gloves!

- Lightweight, ergonomic design makes sampling easy for all operators.

- Vibrant color display makes the screen easy to read under all lighting conditions.

- Customizable user preferences include: screen brightness, volume, language, and date/time format.

- New, advanced sensor technology takes ATP testing to the next level

NEW ADVANCED FEATURES – Beyond Innovation

- Intuitive navigation makes locating test points on the device easier than ever with simple search functions and a quick scroll bar.

- New sample plan feature allows users to assign one or multiple test points to the same sample plan, creating sampling organization and efficiency.

- Sample Plan′s “Shuffle” function allows for randomized sampling of assigned test points.

- Re-test feature allows users to re-sample failed test points to demonstrate and document appropriate and effective cleaning has taken place.

- Assigned calibration test points store results which can later be analyzed with customizable software to help comply with HACCP and GMP programs.

Request a quote for your MVP Icon® here or use the Request Information button to email the company directly.