Together with experts in the field, Hygiena™, a leader in food safety testing, has put together a series of videos to cover food allergies and the most robust allergen control methods to manage them.

Here is the first episode of a 7-part series, which talks about allergies in general and explores the reasons why food manufacturers need to control them.

Summary of Episode 1 - Why do allergens need to be controlled?

Food allergies are abnormal hypersensitivity reactions to an otherwise harmless protein in food. They are a growing global public health concern, which can occasionally even lead to death. Likewise, food intolerances such as glucose intolerance can include a broad spectrum of reactions. In addition, there are illnesses such as coeliac disease - a lifelong autoimmune systematic disorder triggered by gluten found in barley, rye and wheat.

Many regulators across the world have published legislation, standards or guidance documents on how to declare allergens on pre-packed foods. Food businesses need to control allergens:

1. To ensure regulatory compliance;

2. to drive food safety standard compliance; and

3. to protect consumers from harm, and, indirectly protect its brand's reputation.

The impact of food allergens on food businesses can be grave if not properly controlled. In the past decade, product recalls due to undeclared allergens have consistently topped the ranks in multiple countries. Often these recalls could have been avoided if appropriate, simple and robust management plans were in place.

A lack of allergen control does not only lead to consumer reactions and potentially loss of life but it can also lead to food recalls which cost companies large amounts of money, diminished consumer trust, leads to brand damage and ultimately a loss in sales.

Summary of Episode 2 - What is an allergen management plan?

An allergen management plan is an organization’s formal documented plan, describing all the controls and processes that should be in place in order to be able to manage allergens, from start to finish. Typically, allergens need to be controlled at multiple stages of manufacturing: from ordering and receiving ingoing ingredients through to final product packing.

The objective of an allergen control plan is to prevent and mitigate the risk of allergen cross-contact and the presence of undeclared allergens in a final product. Typically, an organization will have a combination of controls in place. This episode will talk you through each one of these.

Summary of Episode 3 - Allergen Cleaning as a Control

Here are some questions to consider when designing an allergen cleaning regime

Is the product soil easy or difficult to eradicate? Does processing alter the product in any way that it becomes more challenging to remove? How clean do you want your equipment to be after cleaning? Do you want it to remove all detectable allergenic residue or do you simply want your equipment to be visually clean? After having carried out a thorough risk assessment review throughout the entire manufacturing process, the next step is to choose the right methods to effectively carry out your allergen cleaning regime.

There are various valuable tools available when building an allergen cleaning regime:

- Mechanical energy, which may include scrubbing, product or water turbulence and high-pressure water jets;

- thermal energy, for example, warm water or hot CIP washes; and

- chemical energy, the action of the cleaning chemical or detergent on food soils.

The extent to which each tool is used will depend on which option offers the most appropriate and practical cleaning method. For example, where it is not possible to use alkaline detergents, a lot of scrubbing may be needed. Likewise, in instances where wet cleaning may not be applied, because it can affect the quality, safety or stability of your product, dry cleaning methods must then be used.

Summary of Episode 4 - Allergen Cleaning Validation and Verification

In Episode 3, you’ll recall us talking about the importance of allergen cleaning to remove allergen residues from shared equipment and utensils. In this episode, we’ll be presenting various allergen controls and touching on validation and verification.

Let’s talk you through the terminology

Validation is the process of gathering evidence to prove that a cleaning regime can effectively and repeatedly remove allergen soils. It is ideally carried out prior to implementation of the regime, essentially to demonstrate that the cleaning objectives have been met. Verification, on the other hand, proves that the validated allergen cleaning regime was performed correctly and remains effective, which is why it is carried out on an ongoing basis.

Neither validation nor verification should be done without completing thorough visual inspections, also known as physical audits. This is complemented by analytical analyses to test for example, finished products, work-in-progress, rinse water, flush material, environmental surface swabs or a combination all of these. When validating, it is best to use a method that yields quantitative results in order to establish whether allergen-cross contact has occurred after cleaning and if it has, by how much. Testing rinse water or environmental surface swabs using rapid and reliable onsite testing kits are ideal for supplementing cleaning verification.

When validating your allergen cleaning regime, make sure to prove that it can consistently achieve your cleaning goal by testing the same worst-case scenario, analyzing the same type of samples, and using the same testing method. If each data set shows that the target allergen residue was removed and no cross contact occurred, you can conclude that the regime was valid.

Without proof, we can never really be sure that an allergen cleaning regime is and will remain adequate and effective, therefore validation and continuous verification is a crucial part of effective allergen management.

In Episode 5 we’ll be highlighting some of the most popular allergen testing methods.

Summary of Episode 5 - AVAILABLE ALLERGEN TESTING METHODS

Allergen testing methods

In Episode 4, we covered the various allergen controls and touched on validation and verification. In today’s Episode 5, we will address all available allergen testing methods.

Laboratory-based methods

Commonly used allergen detection methods can be divided into two groups: There are those that are carried out in a laboratory using specialized equipment, and those that can be performed onsite using little or no specialized equipment.

Laboratory-based methods can be further sub-divided into another two groups: direct and indirect methods.

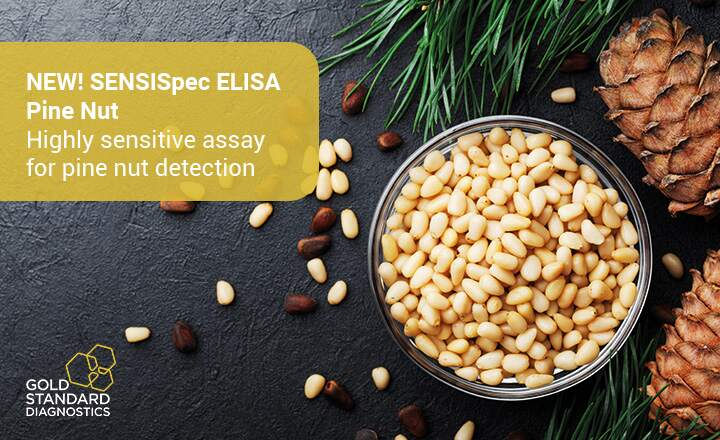

Direct methods detect specific proteins from the allergenic food in question, most often the allergenic proteins themselves such as with ELISA and there is also a targeted proteomics technique available known as Liquid Chromatography-Tandem Mass-spectrometry.

Indirect methods detect a marker associated with the allergenic food in question, for example, its DNA. PCR is the most commonly adopted method here.

Rapid onsite testing methods

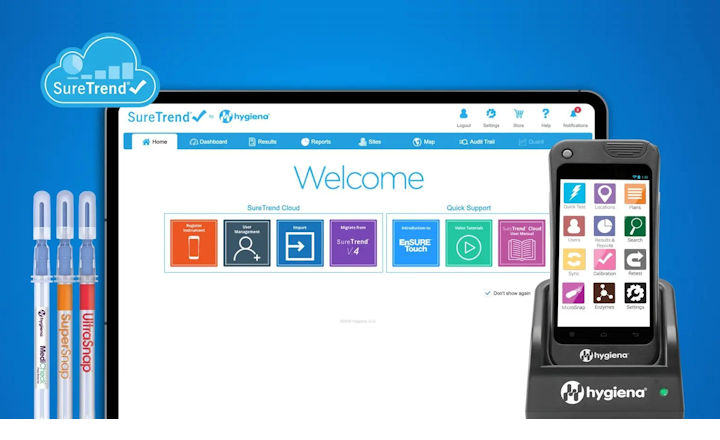

These methods are cost-effective, mobile and operators need no or very little technical skills for their application. Three types have gained popularity in recent years: allergen-specific lateral-flow devices, total protein indicators and sensitive ATP swabs.

Not all allergen detection methods are equal, therefore, it is important to understand, before submitting a sample to a laboratory and prior to choosing a rapid onsite testing kit, what the method or kit measures and whether it is the most appropriate method for your specific set of circumstances.

In Episode 6, we’ll be discussing allergen-specific lateral-flow devices in greater depth.

Summary of Episode 6 - Allergen Specific Lateral Flow Devices

In the last episode, we went over all available allergen testing methods. In Episode 6, we’ll be focusing solely on allergen-specific lateral-flow devices. These are qualitative or semi-quantitative immunochromatographic tests, based on the ELISA technique.

Kit contents

The kits normally contain sterile surface swabs, extraction buffers, dilution buffers, strip tests, disposable pipettes, disposable scoops and sample vials. The four main steps involved are:

- Sampling

- Sample preparation and protein extraction

- Testing

- Reading results

The video explains the testing and result reading steps in detail but ultimately the test strips consist of four zones:

- The sample pad,

- the conjugate pad,

- the test zone, and

- the wicking pad.

The sample extract, containing the target protein, flow from one pad to the next via capillary action and the final zone simply serves as a reservoir for the leftover sample extract.

Allergen-specific lateral flow devices, when used with care, are a valuable tool to assess the efficacy of cleaning and to screen raw ingredients where appropriate.

In the 7th and final episode, we’ll inform you about the total protein indicator kits or total protein swabs, which are designed to detect protein on equipment surfaces.

Summary of Episode 7 - Total Protein Indicators

What are they?

Total protein indicators or total protein swabs are designed to detect protein on equipment surfaces. They cannot discriminate between allergenic and non-allergenic proteins, but the rationale is, if a surface is protein-free, it is reasonable to infer that it will also be allergen-free. The swabs are easy to use, sensitive, cost-effective and practical if you are controlling multiple allergens.

Kit contents

Generally, the kits only have one or two components, the test devices, each housing a swab and its testing liquid as well as a bottle of wetting buffer, if the swabs have not been pre-wetted.

Steps involved

There are three simple steps, which include:

- Sample collection,

- test activation, and

- dry

Systems that can detect protein at very low concentrations require swabs to be incubated in a dry incubation block.

In the video, there is a demonstration of a popular total protein indicator test.

When collecting samples do not focus on flat, easy-to-clean surfaces, rather take swab samples from hard-to-clean areas and accumulation points. Swabbing in such places will give you a better idea of whether the equipment was properly cleaned.

At the end of the test, you can determine whether the protein was present by comparing the colour of the liquid at the bottom of the device to the colour chart supplied.

In conclusion, total protein swabs can be a valuable, low-cost tool to assess the efficacy of allergen cleaning, especially if you need to control multiple allergens.

We hope you enjoyed our 7-part series on robust allergen management. Please feel free to contact us for any further information.

Visit Hygiena or click on the Request Information button below.