When the polymerase chain reaction (PCR) was discovered nearly 35 years ago, it ushered in a revolution in biology. However, at the time of its discovery, few scientists or engineers foresaw how the technology would lead to another type of revolution in food safety.

The technology made it possible to identify the exact species of any organism, based on the tiniest bit of DNA- (or RNA-) containing residue. This is possible due to a very simple process that has now become largely automated. PCR is typically complete within a few hours and works in the following steps:

- Normal, double-stranded DNA from a sample (no matter how small) is “melted,” heated enough so it “unzips” into single strands.

- The DNA is cooled, and primers—specific segments of genetic material—are inserted to mark the beginning and end of the DNA segment to be copied.

- Using the enzyme Taq DNA polymerase (derived from microorganisms living in super-heated thermal pools), new single-stranded DNA lengths are formed, using the original strand as a template.

- The previous step is repeated until millions of identical DNA strands are copied.

These multiple copies can then act as very accurate indicators of a specific species, allowing for precise determinations of the nature (and origin) of any plant, animal, bacteria or other microbe.

In recent years, this technique has been adapted to fit on a silicon chip (operating in a sequencing apparatus). PCR also is now used in what’s known as “real-time,” reading results as they arise during the copying (also known as “amplification”) process, providing valuable quantitative information. Real-time (sometimes known as “quantitative” or “qPCR”) is one of two major types of PCR:

- Real time measures the course of the melting and copying reactions as the amplification process occurs. A fluorescent reporter molecule in each well used for copying measures the beginning, and each cycling step, with more fluorescence indicating more copied DNA, providing an accurate quantitation of the DNA present. Results are available more quickly, because no cell culture or gel electrophoresis is needed to interpret data.

- Endpoint (sometimes called “traditional” PCR, because it was the earliest version of the technique) measures the final DNA concentration after the entire melting, copying and amplification process is finished. Endpoint PCR can take longer than real-time PCR (because of the electrophoresis and other steps), but it can also provide a relatively easy “yes/no” answer to the existence of certain microorganisms.

Originally believed to help better conduct genetic testing, diagnose disease, aid in forensics sciences, and identify ancestry, the method has also been adapted to identifying pathogens in almost every imaginable environment, including food safety, preparation and distribution.

Today’s PCR has become highly automated, making it much easier for nonspecialists to operate the samples, handle the instruments, analyze data, and retrieve invaluable results. The machines themselves also have become more compact and cost-effective enough to be placed in most major food processing facilities and some retail locations, as well as third-party laboratories.

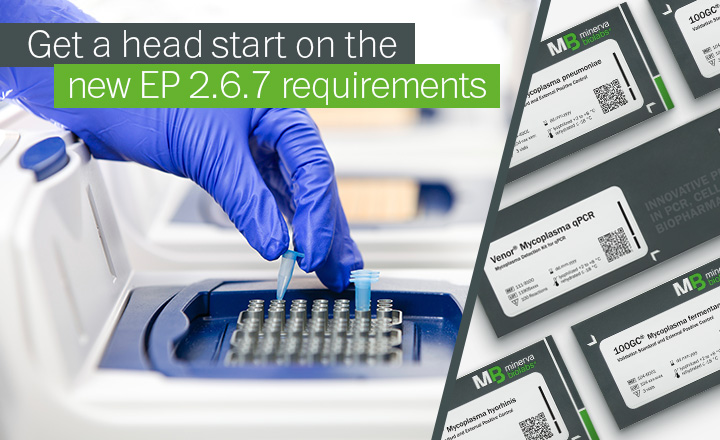

Any PCR technique will depend on high-quality assays to work effectively. An assay will contain target primers, and a probe that is specific for a target sequence. The design of these assays are of very high importance, as they can make the difference between a given test’s success or failure. Fortunately, a wide range of food safety assays are now easily available in endpoint or real-time formats, including to search for E. coli, Campylobacter, Salmonella, Vibrio, and certain yeasts and molds.

In 2017, the potentially deadly microbe Campylobacter was named the most common infectious agent in food, surpassing Salmonella for the first time. Shortly after, the United States Department of Agriculture’s (USDA) Food Safety and Inspection Service (FSIS) adopted Hygiena’s BAX® System Real-Time PCR Assay for screening Campylobacter jejuni/coli/lari in poultry rinse, sponge, and raw product samples. Campylobacter, most often found in poultry and in raw (unpasteurized) milk, is believed to cause more than 850,000 illnesses in the United States each year.

The adoption into the USDA’s Molecular Laboratory Guidebook (MLG), which helps set guidelines for microbiology methodologies used to protect the nation’s food supply, marks another acceptance of the BAX® System by the agency. The system already is an adopted method for detecting Listeria monocytogenes, Salmonella, E. coli O157:H7, and non-O157 Shiga Toxin-Producing E. coli (STEC). Inclusion in the MLG is not a specific endorsement of a method, but an announcement that the BAX® System is one of the techniques used by FSIS labs.

Additionally, Health Canada, the country’s national health agency, included Hygiena’s BAX® System Real-Time PCR Assay as a validated method to screen surfaces for Listeria species, another potentially harmful group of microbes that commonly lie behind food-borne illness. The federal agency also included the BAX® System methodology in its Compendium of Analytical Methods, a guide of official procedures approved and used by Health Canada’s Health Products and Food Branch to determine compliance with government standards and guidelines, as well as investigate foodborne diseases.

The Health Canada Compendium includes a protocol for using the BAX® System assay, which allows a single-stage, 20- to 24-hour enrichment, and real-time PCR processing that allows detection of Listeria species on a range of environmental surfaces common to the food industry. Results are available in less than 24 hours, compared to several days for traditional cell cultures.

PCR has become a standard technique in microbiology, and is quickly being adopted as a “go-to” technique for food safety. New versions of these technologies, such as the BAX® System X5 and Q7 instruments that use traditional and real-time PCR systems, are increasingly within reach of more food processors at every step in the supply chain. Today, this powerful technique can quickly identify potential problems that would have eluded older methods, further ensuring the safety of our food supply.