Food safety issues can arise at any stage in food handling. This is especially true when it comes to allergens, as they can cause severe reactions or even death. As a result, food businesses must implement strict guidelines to ensure finished food product contents match what’s listed on the label. This means establishing a rigid allergen control plan as part of the food safety management process.

Every food processing facility must identify allergen control points within their facility and throughout the manufacturing process. Areas to consider include: ingredient sourcing, raw material storage, plant traffic flow, production line scheduling and segregation (when manufacturing multiple products, some containing potential allergens), food-contact and non-contact surfaces, sampling and testing areas, and even packaging labels and processes for transport, storage, and handling.

Each control point should be evaluated for the risk of allergen introduction and/or cross-contamination. Management of these points requires thorough cleaning and testing as part of GMP requirements and HACCP planning, making these points critical control points (CCPs) - areas where proper control can reduce and eliminate risks. Therefore, they require a proper validation, monitoring, and verification schedule.

For each of these points, there are several ways in which allergen contamination can be controlled.

- Facilities should request allergen statements from all suppliers, documenting what allergens are handled in the supplier’s facility and could be present in any of the raw materials they supply.

- Facilities must test incoming raw materials. Any allergen-containing material must be segregated into designated areas with written product identification to control the use of the material.

- Facilities can use color-coded labeling systems to identify material containing allergens and segregate by color. This color-coding can be applied to bulk storage tanks dedicated to only materials containing that same allergen.

- If a facility is producing multiple products, two options exist:

- Food containing allergens may have dedicated manufacturing areas. Segregation can include simple line separations, but physical barriers work better to prevent dust cross-over from a dedicated line to a non-allergen line.

- Allergen-containing products may be manufactured using a rigid schedule, followed by thorough, verified and validated cleaning processes.

- Facilities must optimize layout and equipment design. This includes limiting the amount of equipment exposed to allergens, proper cleaning of in-process/holding totes, and a defined safety plan, including ways to reduce cross-contamination risks.

- Allergen-containing materials must be segregated during transport, storage and handling.

- Workers can be a source of allergen cross-contamination (clothing, hair, hands and shoes). Training is essential for understanding these risks and how to minimize them through proper hygiene, path movement within the facility, and scheduling only proper personnel in high-risk areas.

- Cleaning and cleaning validation processes must be consistently implemented. There is zero tolerance for allergen presence; cleaning steps must remove all allergens from production equipment.

- Equipment must be easy to clean, including replacement parts. Parts must be cleaned before installation and the processing area must be cleaned post-installation to ensure no allergens were introduced.

- Waste must be removed properly, traveling from the cleanest areas to the “dirty” areas for proper disposal.

- Facilities must validate protocols and implement clean in place processes when possible.

- Facilities must have Standard Sanitation Operating Procedures in place.

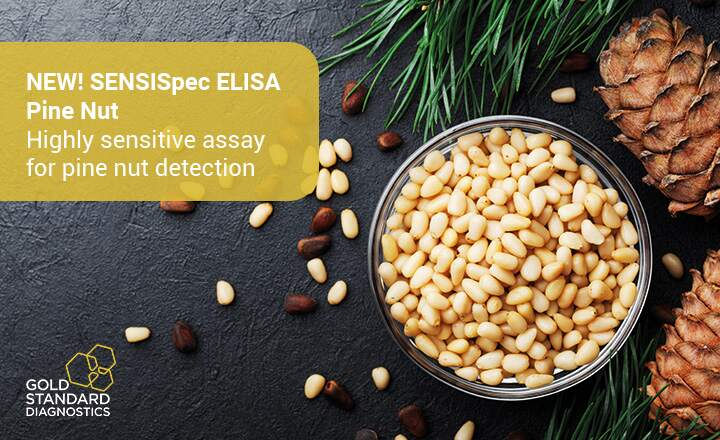

However, the most important, the easiest way to prove cleaning is truly effective is to test samples post-cleaning for the presence of relevant allergens. This is often done by ELISA to obtain quantitative results. Alternatively, easy-to-use, rapid tests can be performed using lateral flow devices to detect if an allergen is present or not.

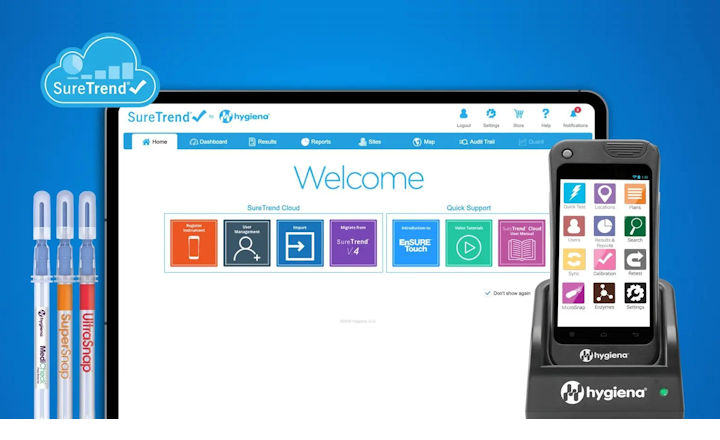

Hygiena™ offers allergen testing kits for common allergens. Our AlerTox® and GlutenTox® ELISA kits are designed to provide both low levels of detection and low levels of quantification. In addition, Hygiena™ offers rapid lateral flow tests for allergen detection (AlerTox® Sticks, GlutenTox® Sticks) and the Cube Reader for GlutenTox® Sticks Plus for quantitative, semi-quantitative, and qualitative data on the amount of gluten present in samples. Data can then be used to track and trend allergen levels for preventative actions.

Learn more about our allergen detection solutions at Hygiena™ or use the 'Request Information' button below.