The global aseptic food and beverage packaging market is expected to reach $35 billion by 2025. Increased demand has forced manufacturers to evaluate aseptic methods for product processing and packaging. Complicating this are increased costs, holding inventory until product release, and the need for more technically specialized staff. To offset these costs, manufacturers are looking for ways to streamline processes, including testing final products for contamination.

This poses enormous challenges for the beverage industry as traditional methods can be inconsistent and are often time-consuming. These methods, primarily culture plates and pH measurements, are manual, error-prone, unreliable, and time-consuming, utilizing valuable resources, space and driving up costs of holding inventory before release.

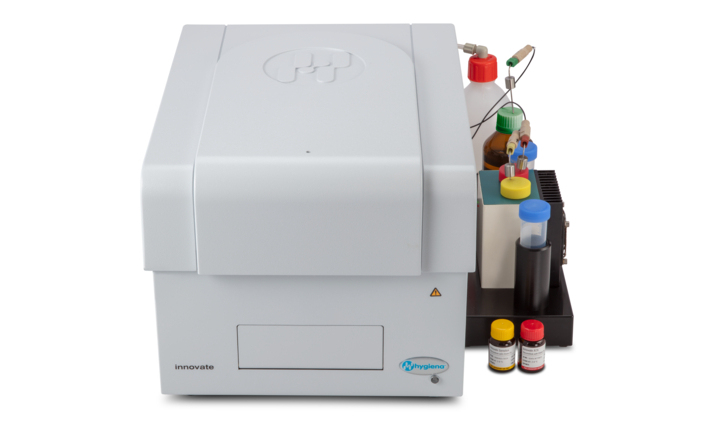

To reduce time to results and streamline laboratory testing, a rapid method is needed that requires little time, space or complicated technology. In addition, the rapid method must be compatible with complex matrices and high acid levels, such as those found in beverage products. All these challenges can be alleviated with Hygiena’s Innovate System. Using the RapiScreen™ Dairy and RapiScreen™ Beverage kits, finished products, from milk to chicken broth to orange juice, can be rapidly sampled and tested after as little as 24-48 hours of incubation post-production.

Using the Innovate System, finished products are sampled and tested using the appropriate RapiScreen kit. The kit contains a proprietary reagent that reduces non-microbial sources of ‘background’ ATP. Thus, any microbial ATP remaining will generate bioluminescence that can be read by the Innovate System software. When optimized, this allows for rapid screening of sample products quickly and accurately, detecting any potential contamination, allowing products to be released to market rapidly and efficiently.

One key advantage of the RapiScreen kits is that they have a strong buffering capacity to neutralize high-acid content in juices and eliminate interference from complex ingredients in dairy formulations. No other rapid method covers such a wide range of products and applications. With this system, results can be obtained in less than 30 minutes, and up to 96 samples can be run at once (no secondary incubation needed as for other growth-based methods). Following product analysis (<30 minutes), a product report is generated for all samples tested, allowing rapid release of products testing negative.

This allows for quick inventory reduction, allowing product to be shipped quicker. Overall, it decreases manufacturing costs – releasing product sooner means more revenue sooner, and faster movement of more product through manufacturing means more volume released at less cost. As a result of rapid detection of low levels of contamination at 24-48 hours, the cost savings for any facility is significant. While QC costs are similar, the investment in finished goods and safety stock is significantly reduced along with the warehouse space costs. In addition, appropriate product release helps prevent recall costs and protects the brand, adding significant benefit to the introduction of a rapid testing system such as the Innovate System.

Learn why you should consider rapid microbial screening of your beverage products using the Innovate System or click on the Request Information button below.