"Magic Lid" - Forcep...

10th May 2018 Content supplied by: Promicol B.V.

Promicol Methods Optimize Sterility Testing of Finished Products

Your sterility testing of finished products is very time consuming, the time until result takes several days and you need a huge storage place to keep all the products until your analysis is done? The Promicol method will be the solution to optimize quality control of your products!

The Promicol method is based on microbial ATP Bioluminescence testing and can be used for a huge variety of finished products which are supposed to be sterile. While traditional microbiological detection methods are slow, often labor intensive and not cost effective, the Promicol range of rapid microbial ATP tests reduces the costs and enables release of product to the market faster.

Samples require a short pre-incubation time before they are automatically analyzed in one of Promicol’s instruments. Due to the unique reagent setup, it is guaranteed that all non-microbial sources of ATP are removed from the sample and that the results reflect the presence of living microorganisms in the tested product. An easy to use instrument as well as software ensures that even staff without microbiological background can perform the testing. Color coding of the measurement results shows immediately if contaminated samples are present and action can be taken straightaway. While producers still need to wait for the results of traditional microbiology the Promicol system already provides the results. In this way costs as well as ‘time-to-market’ are reduced significantly which enables the producer to keep and improve market position.

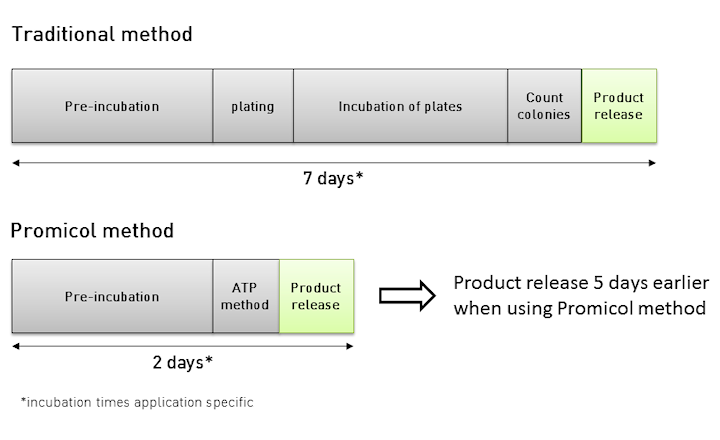

Using Promicol method instead of traditional method it is possible to save 5 days of incubation time (depending on application) and therefore 5 days of storage of produced products which can be released to the market 5 days earlier. Thus, storage costs are reduced significantly while the cash flow is increased. Additionally, despite savings in incubation time, hand-on time of the lab staff is also reduced when using Promicol method which enables reduction of labor costs considerably.

Currently, several companies worldwide producing dairy products, infant food, fruit juices, beverages, soups, sauces, desserts, puddings as well as cosmetic and toiletries products are using our technology to ensure their high quality standards of their products. With many years of experience in the development and manufacturing of ATP Bioluminescence technology customized solutions can be offered for your specific product as well. This tailored ‘customer fitting’ process is a key feature of the unique value added approach of Promicol to our customers. This assures high reliability in determining low levels of microbial contamination in finished products where the ‘one size fits all’ solution will not suffice and the development of ‘tailored’ assays is imperative.

Improve the reliability of your quality control and make it more efficient together with the Promicol partnership. In general, long-term relationships are more important for Promicol than the short term fix. Customer relation and customer satisfaction are key words within the mission statement of Promicol. We at Promicol believe that only a close relation with our customers can result in a perfect customer solution. To build a long-lasting relationship it is imperative to build trust, exchange expertise and increase innovation. We want to make ATP work for you, together with you.

Visit www.promicol.com

Tags:

Date Published: 10th May 2018

Source article link: View

Related news

"Magic Lid" - Forceps-free, Effortless